New Trend Welding Robot Arm Price Self-propelled All-scene Welding Robot for Large Parts

New trend welding robot arm price Self-propelled All-scene Welding Robot for Large Parts

This system is committed to solving the fusion welding operation problems of multiple types and specifications, small batches, etc. Traditional welding relies on matching fixtures and personnel skills to complete product manufacturing. Due to the solidification of traditional welding, there are shortcomings in product upgrades, process improvements, and new product launches. Through system program guidance, the unit allocates and combines the processes of the preset devices internally, then the system will gain corresponding welding programs and data processes and make a record that can be called up when needed. When product upgrades, process improvements, and new products are launched, simply adjusting the program can efficiently meet production needs while reducing tooling production cycles and costs. The concept of this workstation is to convert the mode of production from traditional hardware production capacity storage to software program storage with only one demonstration.

Work Capacity: Welding

object: carbon steel plates and section bars (thickness between 4 and 25mm); tolerance of linearity and flatness of the board surface within 2mm (welding area size requirement); the size deviation after laser cutting controlled within 1mm without distortion or slag hanging; the size of the part with 1×1.5×1 meters; maximum single piece weight not exceeding 120KG A small and exquisite appearance, with remote control operation for movement, makes it more flexible and suitable for complex ground moving and welding.

object: carbon steel plates and section bars (thickness between 4 and 25mm); tolerance of linearity and flatness of the board surface within 2mm (welding area size requirement); the size deviation after laser cutting controlled within 1mm without distortion or slag hanging; the size of the part with 1×1.5×1 meters; maximum single piece weight not exceeding 120KG A small and exquisite appearance, with remote control operation for movement, makes it more flexible and suitable for complex ground moving and welding.

1.The tracks enable Robot to operate on the soft or muddy ground, by largebearingarea, low grounding pressure, low sinking, andlowrollingresistance.

2.Good off-road maneuverability enables it to move on uneven surfaces, cross obstacles, climb steps with small gradients, and have superior performance in climbinghillsandditches.

3.Thegrouserof thetrackmakesit less prone to slip. It has a good tractionandadhesionperformance, which is conducive to exerting greater tractionforce

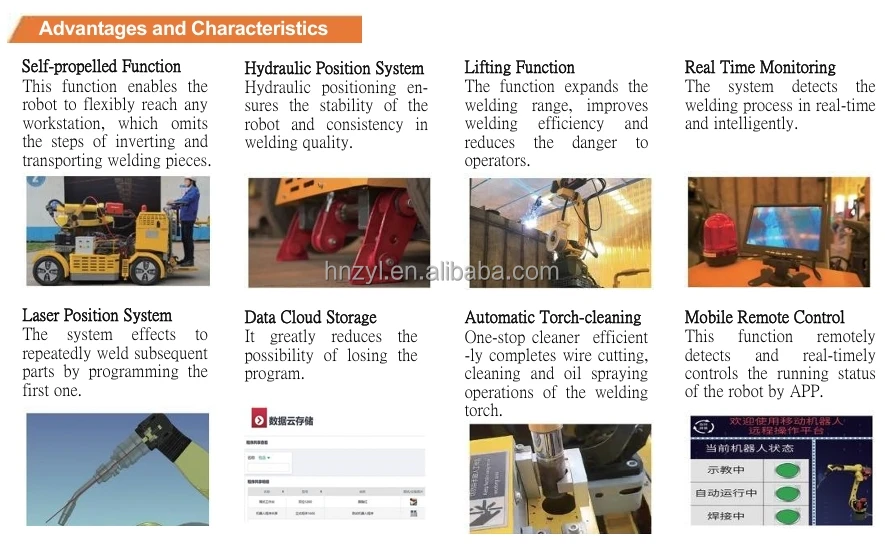

Function Introduction

Contact Sensing Contact sensing can automatically identify the deviation between the actual positionof thepartandthepositionrecordedby thetouchof thecontact sensor on thepart,andcompensate for thisdeviation in thesubsequent actualwelding process.

ArcTracking Duringtheswingprocess,weldseamtracking isachievedbasedonchanges in current.

Multi-layer&Multi-trace The stacking times and rules of the welding path are designed through instructionsbyoncebasicpathrecordedbyiPendant, tomeet theweldingneeds.

Collision Detection Incaseof accidentsor operational errors, emergencymeasureswill happen to

minimizeequipmentdamage.

minimizeequipmentdamage.

Swing Welding It supportssine, arc, and8-shapedswingwelding, and theswingreferencecan

besetbyselectingthecycleor length.

besetbyselectingthecycleor length.

Discontinuous Welding Itsupportshigh-speedintermittentwelding,usedforT.I.Gwelding.

IdleRunning Function After completing the trajectory teaching, the robot can enter the idle running function. At this time, the robot doesnot start thearcbut only runs the robot trajectory,whichisconvenient forquicklydetectingthecorrectness.

|

Number of axes

|

4 axis / 6 axis

|

|

Repeatability

|

±0.08mm

|

|

Maximum wingspan

|

1000-3100mm

|

|

Ambient temperature

|

0-45°

|

|

Weight

|

50kg-680kg

|

|

Payload

|

Customized on demand

|

|

Gripper

|

Customized on demand

|

The palletizing robot has the characteristics of high positioning accuracy, fast running speed and wide working range. In the control system, the built-in uniform stacking operation model can teach the operation, which is simple and convenient. Easily complete the transportation task. The handling robot is mainly suitable for large load and large range of work places.

Product details

Robot arm

The robot arm is made of aluminum castings and processed by CNC machining center. The surface is sprayed with plastic to achieve a beautiful appearance.

Machine manual fixture

The reclaiming chuck rack is installed on the end flange. The suction cups are installed on the chuck rack with appropriate gravity and quantity according to different products. The reclaiming jig is easy to install and adjust, and has a wide range of applications

Reserved wiring hole

The robot arm shall reserve a wiring hole, which is beautiful and does not hinder the operation of the robot arm. The end shall reserve a gas pipe interface and a data cable connector.

Robot control cabinet

An intelligent motion control system based on industrial computer technology is adopted, and the all digital servo module provides driving power for the AC servo motors of the six joints of the robot.

Teaching pendant

1.Ergonomic design, comfortable and light operation 2.All Chinese display, friendly interface 3.Display with different screen sizes according to needs 4.Two way safety switch, fully ensuring the safety of personnel operation 5.Equipped with USB interface, support the import and export of teaching programs

Robot fence

Through the establishment of the protective net, only the loading channel and the unloading channel are reserved. Isolate the

equipment from the staff to ensure their personal safety.

equipment from the staff to ensure their personal safety.

Customer case

Application

Robots are widely used in gluing, woodworking and drilling, ceramic handling, slaughtering, spraying and other fields. They are equipped with special customized software to facilitate user operation. Improve the degree of automated production, work efficiency and product quality.

FAQ

Q: How about the quality of your palletizer?

A: Our factory has 14 years of machining experience; All our machines have passed ISO9001 and SGS Certificate, CE certificate; It has been exported to many countries and regions; It has won good reputation from customers.

Q: What's the price of your palletizer?

A: No matter the price is good or bad, we regard quality as the life of the factory. Quality first, quality first

The foundation will certainly let you get a reasonable and satisfactory price!

Q: Can you send me the video to see how the machine works?

A: Of course, we have made videos of each machine and uploaded them through our chain address. Please. Contact us and we will send you the machine video.

Q: How about your installation service and sales service of palletizer? A: 1 > the warranty period is two years. If you need, we will provide spare parts or send engineers to your side. We will serve you at any time, 24 hours and 7 days. 2> We have prepared technical manuals and operation videos for our customers to show, so that the installation and use of the machine will be easy. 3> It is free to train your workers in our factory or near you or through video.

The New Trend Welding Robot Arm Price Self-propelled All-scene Welding Robot for Large Parts is evocative, to say the least, but that's why you're drawn to it in the first place.

Inventory Last Updated: Feb 06, 2026

Inventory Last Updated: Feb 06, 2026