This item is currently unavailable

|

Model Number

|

tsdz2 centro motore

|

Voltage

|

DC 24V/36V/48V

|

|

Set Speed

|

25km/h

|

Weight for motor

|

3.60kgs

|

|

Max speed

|

40km/h

|

Certification

|

CE, RoHS

|

|

Power

|

250W

|

Warranty

|

2 years

|

|

Teeth Plate

|

42T

|

Crank length

|

170mm

|

|

Wheel size

|

Adjustable

|

MOQ

|

1 Piece

|

|

Origin

|

suzhou, jiangsu

|

Function

|

conversion kit

|

|

Max torque

|

80 -90 N.M.

|

Port

|

Shanghai

|

tsdz2 centro motore contains :

a) Motor intergrated with controller and torque sensor;

b) LCD display, several different models are available for selection;

c) Detective sensor;

d) Crank;

e) Teeth plate;

f) Operator;

g) Tool for installing Accessories for installing.

h) Brake level and throttle are optional;

Why choose the little motor- TSDZ2 Mid drive motor?

- Supports up to 58.6V (48V mid motor) input voltage.

- Fits 95% of standard bike frames with 68-73mm bottom bracket built in torque and cadence sensor- this results in much smoother acceleration than any cadence sensored mid motor.

- Easy to install. Kit includes all installation parts and tools.

- The motor has an extra support mount - resulting in a much more reliable install.

- No throttle - this system is a pure pedelec; motivating you to pedal harder and go farther.

- 80Nm of torque is almost twice as much as a hub motor and can help you climb up any hill in your way.

TSD2 Mid-drive System assembly process

1. Motor installation

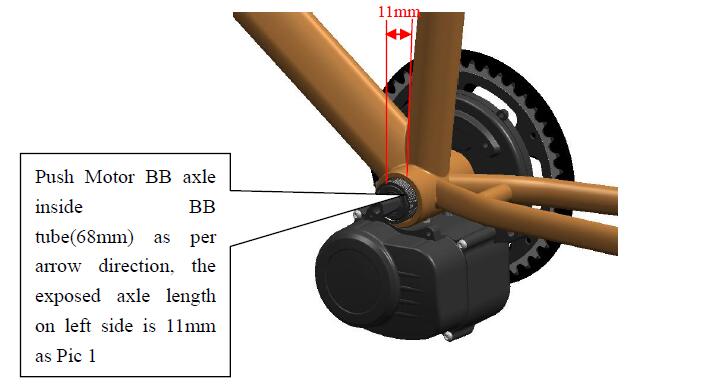

Step 1: the motor shaft sleeve in the direction of the arrow push bike five-tube length of 68mm five-pass pipe, the length of the sleeve is exposed to 11mm, as shown in Pic1.

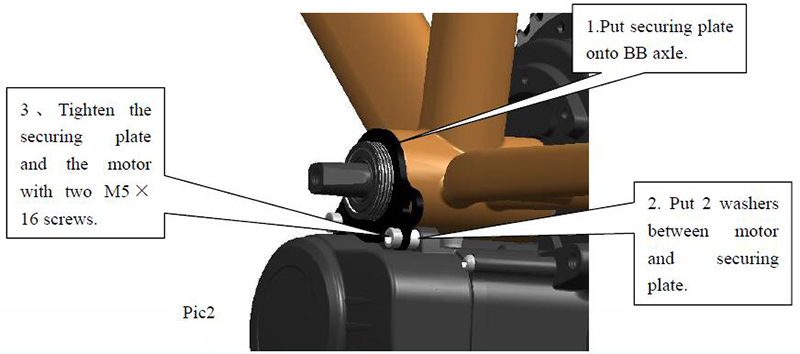

Step 2: Install the reinforcing plate. See the Pic2.

1. the reinforcing plate set in the five-axis

2. two aluminum washers placed between the reinforcing plate and motor home

3. with two socket head cap screws M5 × 16 will strengthen the locking plate and motor home

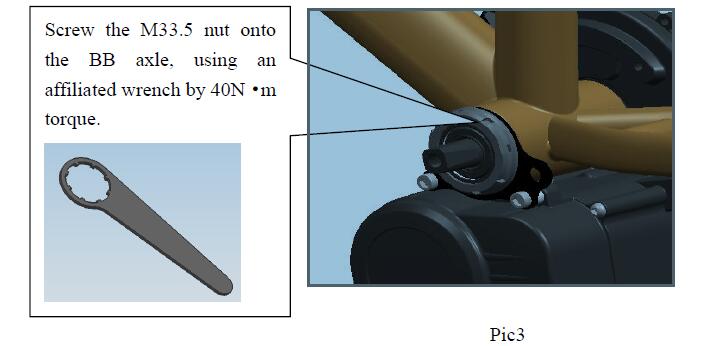

Step 3: M33.5 nut screwed onto the sleeve axis, with a special tool to tighten the locking force of 40N · m.See the Pic3.

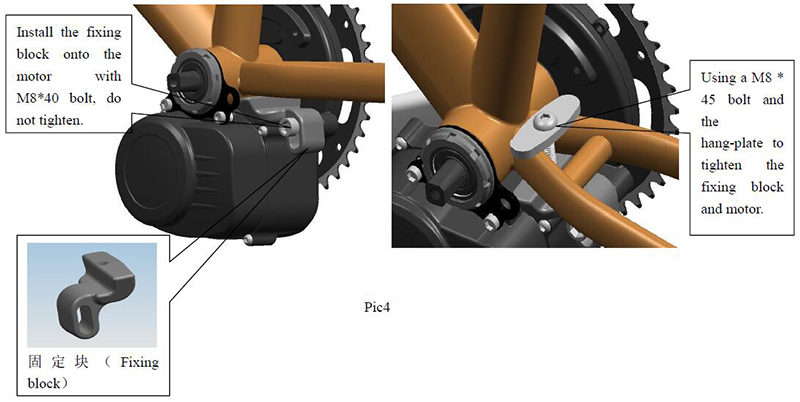

Step 4: fixing the motor and the frame. See the Pic4.

1. M8 * 40 screw connections fixed block and motorhome body stud hole preload.

2. with the ball screw M8 * 45 screw holes through the fixing plate fixed on the block with the fixed locking.

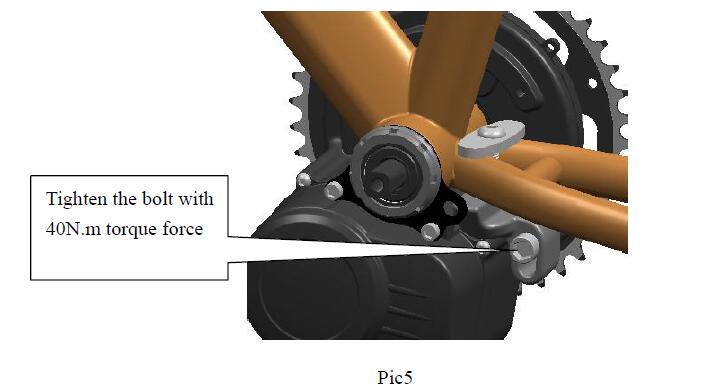

Step 5: 40N · m of force tighten M8 * 40 screws (final lock). See the Pic5

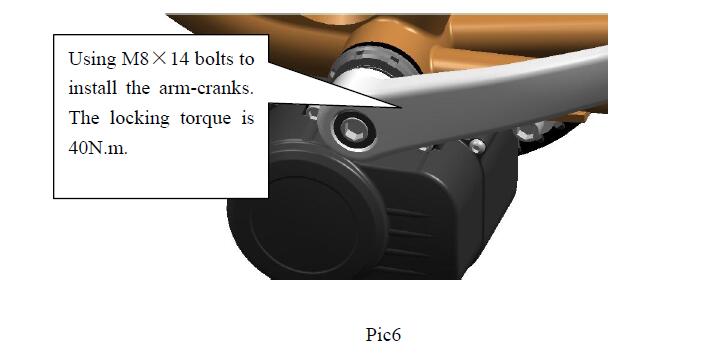

Step 6: Install cranks. See the Pic6.

Install left and right crank with M8 × 14 hexagon screw locking torque is 40N · m.

2. Meter Installation

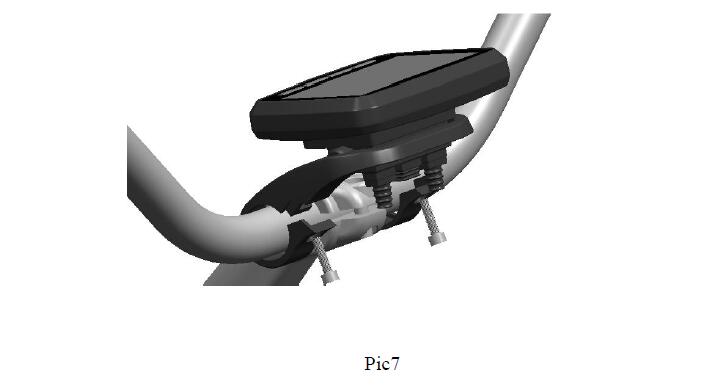

Step 1: Install the instrument. See the Pic7.

With two M4 × 14 hexagon socket head screws and two M4 nuts square meters is fixed at a position shown in the Pic7.

Bracket Specifications: φ32, there are adjustment ring.

The second step, the left-hand operation switches installed. See the Pic8.

With two M2.5 × 10 hexagon socket head cap screws at the position illustrated operation switch fixed

Inventory Last Updated: Oct 22, 2025