Lwt Cobot palletizer collaborative robot palletizer for cartons and box

The palletizing robot is an organic combination of machinery and computer programs. It provides higher production efficiency for modern production. Stacking machines are widely used in the stacking industry. The palletizing robot greatly saves labor and space. The palletizing robot operates flexibly and accurately, is fast and efficient, has high stability, and has high work efficiency.

The palletizing robot system adopts a patented coordinate robot, which occupies a flexible and compact installation space. The idea of being able to build an efficient and energy-saving fully automatic block molding machine production line within a small footprint has become a reality.

The palletizing robot system adopts a patented coordinate robot, which occupies a flexible and compact installation space. The idea of being able to build an efficient and energy-saving fully automatic block molding machine production line within a small footprint has become a reality.

|

Item No.

|

LW-RP165

|

LW-RP210

|

|

Palletizing Height

|

1650mm(Including Pallet)

|

2100mm(Including Pallet)

|

|

Speed

|

12PPM

|

12PPM

|

|

Max Load

|

30KG

|

30KG

|

|

Power Supply

|

200-240V 50/60Hz

|

200-240V 50/60Hz

|

|

Air Comsumption

|

400NL/MIN

|

400NL/MIN

|

|

Temperature Range

|

0-55ºC

|

0-55ºC

|

|

Base style:

|

Installation Base

|

Lifting Base

|

|

Material

|

Aluminum

|

Aluminum

|

|

Communication Type

|

EtherCAT

|

EtherCAT

|

|

Control/PLC

|

Keba

|

Keba

|

|

HMI

|

Keba

|

Keba

|

|

Reducer

|

Nidec

|

Nidec

|

|

Specification

|

3950*1724mm

|

3950*1724mm

|

|

Pallet Working Radius

|

1600mm

|

1600mm

|

|

Pallet Size

|

1250*1250mm

|

1250*1250mm

|

|

Positioning Accuracy

|

±0.04mm

|

±0.04mm

|

|

Safety

|

Safety Fence, Light Curtain(Optional, Recommend Make it local)

|

Safety Fence, Light Curtain(Optional, Recommend Make it local)

|

Collaborative palletization redefines the concept of“'ease of use”:

Installation and re-adjustment can be completed within 2 hours

New path set-up within 5 minutes.

8-10 boxes can be stacked per minute.

Up to 800 stacking paths can be set.

New path set-up within 5 minutes.

8-10 boxes can be stacked per minute.

Up to 800 stacking paths can be set.

300mmx1200mm。Maximum tray size1300mmx1200mm

Two products can be stacked simultaneously.

With label orientation function.

Two products can be stacked simultaneously.

With label orientation function.

Advantages

Simple programming

Visual programming is simple and efficient, and ordinary employees can easily manipulate robots without having to master the programming language.The programming mode can be learned in half an hour and simple programming can be completed in 1 hour.

Safety and stability

Industrial grade force-sensor with high reliability and safety;

Visual programming is simple and efficient, and ordinary employees can easily manipulate robots without having to master the programming language.The programming mode can be learned in half an hour and simple programming can be completed in 1 hour.

Safety and stability

Industrial grade force-sensor with high reliability and safety;

Support 10-level collision detection and sensor safety detection;

without loss of safety function in case of single fault;

Flexible deployment

Integrated design, light and flexible, small footprint area;

without loss of safety function in case of single fault;

Flexible deployment

Integrated design, light and flexible, small footprint area;

Workstation deployment of new task setting is simple,quick and efficient;

Flexible Production

With fast switching of various functional scenarios,flexible production can be realized by human-machine cooperation,

dual-computer cooperation and multi-computer cooperation.

Flexible Production

With fast switching of various functional scenarios,flexible production can be realized by human-machine cooperation,

dual-computer cooperation and multi-computer cooperation.

Pre-sales:

According to client-specific machinery or automatic product line requirement, supply reasonable machine sketch map, quotation, and similar video for client ref first.

During Sales:

1) Depends on the client's need to custom base on the standard machine.

2) Repeat 20 ongoing hours testing equipment

operation stability.

operation stability.

3) Execute GMP certification for the equipment and materials used in the production process requirement and specification strictly.

After-Sale:

1. During the epidemic, we support senior engineers to provide one-by-one video guidance; And other times, we will assign professional engineers to customer companies for installation or maintenance services according to customer needs; 2. Supply systematic operation training for client workers. 3. Guarantees all equipment (except human factors) within one year, lifetime maintenance services. 4. After the client use the machine for several years, we can provide a detailed refurbishment program, the original equipment and replacement of hardware and software upgrades, extend machine service life for more than 3-4 years. 5. If quality problems arise, the supplier provides technical support and timely supply wearing parts.

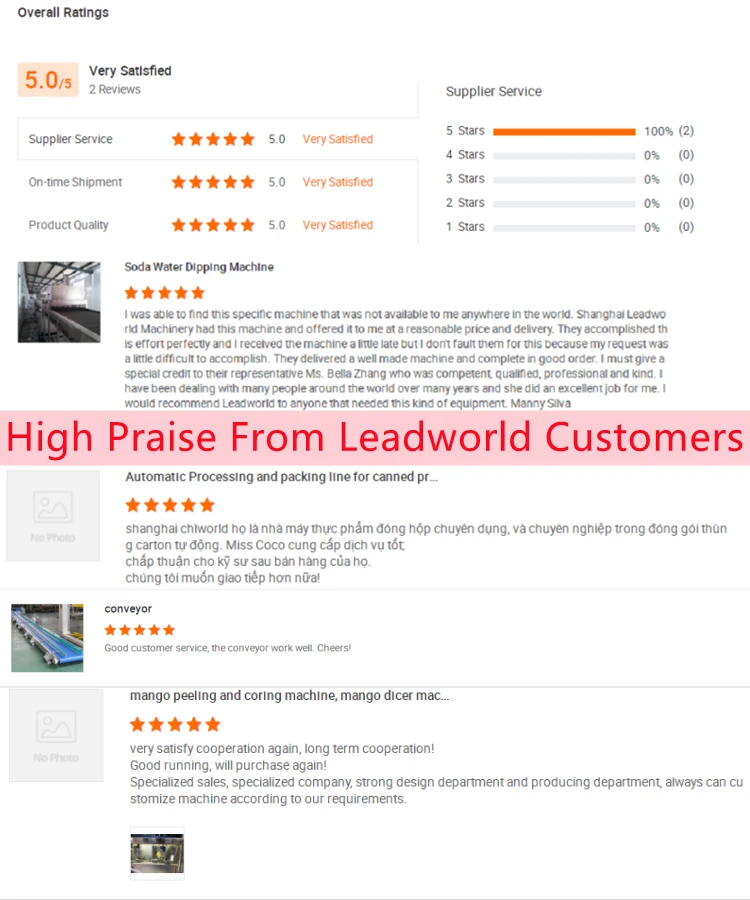

FEEDBACKS

FAQ

Q.Are you a manufacturer or trading company? A: Yes, We are a manufacturer verified by ALIBABA and we have our own R&D and Production team Q: What are your company’s main products? A: All production Packaging line end of the line and Related Packaging Machinery. If this is not the machine you want, please visit our other machines. Q.Where are you located? Is it convenient to visit you? A: Yes, We are located in Shanghai, traffic is very convenient. Welcome to our factory anytime Q: How can you guarantee the quality? A: 1. We have completed the working system and procedures and we follow them very strictly. 2. Our different worker is responsible for different working process, their work is confirmed, and will always operate this process, so very experienced. 3. The electrical pneumatic components are from world-famous companies, such as Germany's Sieme ns, Japanese Panasonic, etc. 4. We will do strict test running after the machine is finished. 5. Usually our machines are certified by CE. Also, Leadworld machines can be passed the relevant certification standards of the customer market according to customer needs Q: Can you design the machine according to our requirements? A: Yes. We not only can customize the machine according to your technical drawing but also can he new machine according to your requirements. Q: Can you offer overseas technical support? A: Yes. We can send the engineer to your company to set the machine and train your worker if needed. Q: Why do our customers trust and choose us? A: 1. Leadworld is a factory 2. We have stocks 3. Delivery fast 4. Senior engineer team 5. Competitive price 6. Strict quality control 7. Over 10 years customization experience 8. Provide a test report if you need 9. Excellent after-sales services 10. Advanced machinery and equipment If you have more questions about our product, please send us an inquiry below. Commonly, you will get a reply in 24 hours. Thank you

E smart way is first Chinese online shop dedicate to short distance transportation whether it is for fun or commute, we offer Free Shipping for Lwt Cobot palletizer collaborative robot palletizer for cartons and box